Waste Heat to Power (WHP) Generation

From small to big companies,

most of the heat generated is not used and considered a waste.

By harnessing this “waste heat” using a WHP generator it is possible to produce electricity, allowing businesses to both save energy and help protect the environment.

Reducing electricity consumption

Waste heat can be turned into electric power.

Protecting the environment

By reducing our electric consumption we also reduce the amount of fossil fuel needed to produce electricity thus lowering our carbon footprint.

Corporate Social Responsibility (CSR) and Sustainable Development Goals (SDGs)

CSR and SDGs are gaining ever more recognition nowadays as we realize the importance of the environmental issues ahead of us. In this context a Waste Heat to Power generator can be a great asset to help a company attain its CSR goals.

We select the WHP system based on several parameters such as:

The temperature

The amount of heat produced

The type of Waste Heat

| Electric power facilities |

Heat source |

Typical applications |

| Organic Rankine Cycle technology (ORC) |

Medium or low temperature |

Metal heat treatment, ceramic manufacture, glass production, incineration systems, cogeneration systems etc. |

| Stirling engine |

High temperature |

Garbage incineration plant, woody biomass boiler, industrial scale incineration systems, Industrial furnaces(for ceramic, firing, melting, combustion etc.) |

| Small steam-electric generator |

Steam |

Food industry, petrochemical industry, electronic component manufacturing etc. |

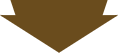

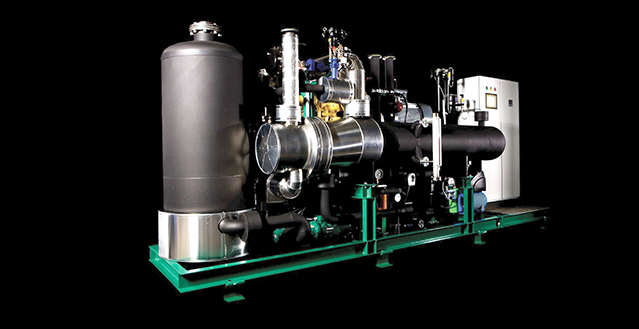

● ORC (Organic Rankine Cycle)

● ORC (Organic Rankine Cycle)

This system is a steam engine using organic matter instead of water, waste heat can be turned into electricity at medium or low temperature; 90-250 degrees.

ORC engine can also function using geothermal and exhaust gas heat.

● Stirling engine

Gas expand and contract depending on its temperature, by repeatedly warming and cooling a gas in an airtight chamber we can harness this movement to drive pistons and generate power.

● Small steam-electric generator

- Electric generator using waste steam

Small steam-electric generator can use steam coming from:

Other machines

The flash steam from recovery system

- Steam Screw Expanders (SSE)

The SSE is a generator adapted to small scale plants and specifically made to answer the common problems faced concerning small scale steam based power generation:

Change in flow

A small steam volume

Low-pressure

With a SSE it is possible to generate energy efficiently in small plants and at low cost.

Installation Support

We support you from the feasibility study to the installation and operation of your generator.

WHP project development planning

*Depending on each case we provide tailor made solutions to ensure your utmost satisfaction.

| Feasibility study |

The most important points for WHP are:

the quantity of gas

the way of recovering heat |

| Inquiry phase |

Research |

- Used fuels

- The principal characteristics of the gas (temperature, pressure, amount of gas flowed, composition)

- And the provenance of waste heat and how it is captured

- The amount of available cooling water

|

- The current state of the project

- Installation place

- Plumbing

- Confirm blueprints

- Measure the gas quality(as necessary(extra charge))

|

| Installation support |

For each specific case we carefully select the best products and most appropriate type of fuel to suit our client needs. We can also advise our clients about the characteristics and the cost of:

The equipment

The installation

The fuel

The maintenance

The management |

| Advice for system |

Estimation, fund adjustment |

- Power calculations

- Manufacturer selections

- System architectures operating

|

- Initial cost estimation

- Running cost estimation

- Help acquiring public funding or public subsidies

- Profitability analysis (return on investment)

|

| Support |

- Construction planning

- Installation adjustments

- Test Operation

Please contact us for more information about WHP.

|

● ORC (Organic Rankine Cycle)

This system is a steam engine using organic matter instead of water, waste heat can be turned into electricity at medium or low temperature; 90-250 degrees.

● ORC (Organic Rankine Cycle)

This system is a steam engine using organic matter instead of water, waste heat can be turned into electricity at medium or low temperature; 90-250 degrees.